Securing Steel Frame Buildings to Foundations

Creating an enduring steel structure begins with properly securing the metal framework to a stable foundation. While couplers temporarily hold framing components together during building, permanent steel anchors prevent the assembled building from shifting, racking or lifting. Robust connections between the foundation and steel framework provide critical load transfer to ground supports below.

Anchor Bolt Types

J-style anchor bolts rank among the most common methods for fastening steel posts directly to concrete pads or piers. Hot-dipped galvanized steel J-bolts feature 90-degree angles that drop into pre-set sleeves filled with non-shrink grout or epoxy. Tightening the nut above fastens down vertical columns securely. Adding washers and double nuts protects against loosening.

For girts lining ground-level walls, drilled-in concrete screw anchors offer another dependable fastening option. Unlike hit or miss post-installed expanding anchors, screw anchors cut into concrete for superior pull out resistance with threaded steel grade 8 mounting bolts. Installation requires nothing more than a hammer drill and impact driver.

Here is an in-depth explanation of anchor bolts for slab foundations:

Anchor bolts play a pivotal yet often overlooked role connecting buildings to their concrete foundations. These steel fasteners bolt through the base plates of structural columns, beams and walls, anchoring them firmly into the cured concrete below. By resisting upward and lateral forces, anchor bolts prevent the entire framework from shifting off the foundation over time.

Installation Basics

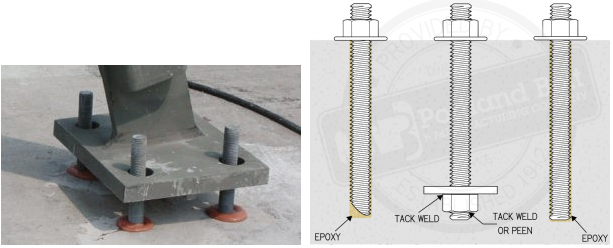

Anchor bolts insert into wet concrete slabs before drying and curing. Bolts drop into preset sleeves or holes lined with cardboard or plastic cones. This prevents wet concrete seeping down and coating the threads during pouring. Once the slab sets, the void forms a sleeve to receive the threaded bolt shank. Tightening the nut and washer atop then draws the base plate snugly down onto the foundation.

Common Anchor Bolt Types

J-Bolts: Formed in a “J” shape, these rods contain a 90-degree bend so that the threaded end inserts horizontally into the slab while the bolt end stays vertically oriented. J-bolts allow easy fastening of vertical steel posts directly through base plates.

Headed Bolts: Featuring an integrated hex or square head protruding above the concrete surface, these specialty anchors provide a fixed fastening point. The bolt head also prevents pull through.

Double-Headed: With topped and tailed heads that remain encapsulated inside the slab, these “all-thread” style anchors offer adjustable connection points above and below the foundation layer.

Material Considerations

Steel grades 36 and 55 comprise standard anchor bolts. But certain applications demand stainless steel grades 304 and 316 for superior environmental resistance. Hot-dipped galvanizing also protects external threaded segments. For extra longevity in corrosive environments, choose epoxy coated or ceramic filled coatings which further isolate the steel.

Anchor Bolt Sizing

Several factors determine suitable anchor sizing and spacing patterns. This includes slab thickness, concrete compressive strength, and overall building dimensions. Always defer to structural engineering guidance based on regional seismic data and wind shear calculations too. Insufficient anchors cause ineffective load transfer which can lead to catastrophic building failures.

While hidden from view, properly installing the right anchor bolts with compression sleeves for your structure’s expected loads keeps buildings of all sizes safely secured over the long run.

Critical Anchor Locations

Anchor bolt spacing varies per engineering recommendations, but typical spacing falls between 6 and 8 feet. Anchors always occur at critical joints where major beams meet columns. This prevents frame sidesway by securing the tall wall posts and roof beams comprising the building skeleton. Anchoring intermittent rafters likewise maintains overall structural integrity across the entire envelope.

Hardware Specs

Minimum anchor bolt diameter sizes range from 3⁄4 inches for small steel frame buildings to over 1 inch for commercial structures. Yet even robust anchors prove pointless if the concrete underperforms. Always ensure slab compressive strength meets required PSI ratings before torqueing down connections. Reinforcing footers with rebar and testing sample cores helps confirm strength.

While the steel frame provides primary wind and gravity load resistance, pure anchoring strength prevents the building from literally being blown or pushed off its foundation. Specifying quality steel fixtures secured deeply into structural concrete ensures the metal bones of barns, warehouses and other vital buildings remains locked in place no matter the forces exerted.