Disadvantages to Consider with Light Gauge Steel Construction

Light gauge steel framing builds momentum across construction sectors from homes to commercial buildings thanks to durable engineered components offering time and cost savings over conventional building methods. But despite widespread merits, limitations exist that owners, architects, and builders should acknowledge when assessing the viability of certain projects. Let’s examine key disadvantages that need awareness before proceeding.

Susceptibility to Buckling if not engineered properly

While cold-formed light gauge steel boasts immense tensile strength resisting forces pulling connections apart, relatively thinner profiles risk buckling under extreme compressive loads. Adding supportive sheathing, diagonal bracing, and doubling up members compensates plenty for typical builds. However imperfect installations or excessive weighted use requires frequent checkups.

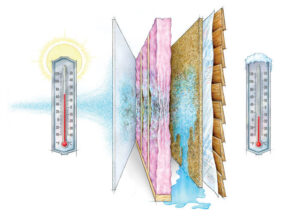

Heat Conductivity Concerns

The innate thermal conductivity of metal materials becomes problematic in some climate extremes without sufficient insulation barriers. Both hyper-insulating and radiant barrier techniques properly address these engineering hurdles by paying close attention to dew points. Special fasteners like thermal breaks also help.

Expertise Essential for Large Spans

The deceptive simplicity of stick framing with light steel belies subtleties in managing load transfers, preventing flex failures or bracing tall expanses adeptly. Occasionally inexperienced builders misapply components stacked beyond prudent capacity. Vetted Floor plans should inform section use specifications and reinforcement needs at scale.

Flammability Considerations

While steel itself does not fuel fires intrinsically, some coated thin gauges and foam insulation in sandwich panel assemblies may enable flame spread absent appropriate firewall barriers. Careful material selection and compartmentalization containment strategies negate risks for occupants along with automatic sprinkler systems.

Benefits Of Light Gauge Steel for Metal Shops & Garages

Building with cold-formed light gauge steel framing members continues growing exponentially worldwide replacing conventional stick framing utilizing dimensional lumber from surface walls to structural buildings. Fueled largely through significant upsides spanning durability, design flexibility, affordability, and sustainability, light steel solutions empower commercial, institutional, and residential structures to meet demanding performance expectations across virtually all use case scenarios.

Proven Durability Measured in Decades

Precision-manufactured gauges retain reliable integrity as stable building skeletons spanning over 60 years before corrosion, rot, or pest vulnerabilities undermine dense treated woods in half the time. This lifecycle advantage amortizes initial investments for enduring ROI protecting valuable assets and operations.

Customization Using Interchangeable Components

From curved walls to dramatic interior volumes, cold-formed load-bearing C channels and box section studs enable creative architectural liberty that other materials can’t match while accommodating infinite structural add-ons over time. The permutations stretch limited only by imagination and sensibilities more than physical constraints.

Lighter Weight and Safer Handling

Unlike dense lumber or awkward wide flange steel, thin-formed framing proves friendly for manual maneuvers by smaller crews. The components lift into alignment more nimbly and precisely while accepting cladding skins for rapid enclosures fine-tuning protective shells in all weather.

Inherent Sustainability Attributes

Steel recycling infinitely without quality degradation coupled with manufacturing economies and lighter product weight reducing transportation impacts make cold-formed framing a standout green building choice. LEED and other certifications acknowledge measurable conservation benefits realized across building lifecycles.

In summary, hot-rolled structural steel earns a purely robust reputation although cold-formed complements make hitherto impossible structures achievable through customizable modular components built to endure. This innovative dependability expands construction potential greatly in the 21st century.

By acknowledging limitations thoughtfully during design phases, engineers and builders tailor robust structures minimizing negative steel building performance potentials through proactive planning. This keeps projects on track delivering durable and cost-effective buildings safely built to last using light gauge steel solutions.