Do I Need to Ground My Steel Garage Kit When Building It?

When constructing a steel garage or any other metal building, an important consideration is whether you need to ground the structure. Grounding provides an intentional path for electricity to safely flow into the earth in the event of a short circuit or electrical fault. This helps prevent electric shock and damage. So do metal garage kits need to be grounded? Let’s explore the details.

Why Grounding is Recommended

Industry experts overwhelmingly recommend grounding metal buildings, including steel garage kits. Here are some of the main reasons why:

Overall Safety: Properly grounding the metal framework protects people from electric shock. In the event of an electrical malfunction, it allows the current to bypass occupants and dissipate into the ground. This is crucial for safety.

Surge Protection: Grounding helps divert stray electrical currents away from electronics and valuables stored in the garage during lightning strikes or power surges. This protects vehicles, tools, appliances, and other items from damage.

Code Compliance: Most building codes require the grounding of metallic structures like steel garage kits as a safety precaution. Failing to do so likely violates local regulations. Checking your code requirements ahead of time is advised.

Added Resale Value: A grounded steel garage reassures prospective buyers and ensures you can legally sell the property without first needing to update the structure to code.

How to Properly Ground a Steel Garage

Grounding a prefabricated steel garage kit involves creating a low-resistance metallic path from the steel frame into moisture-rich soil. Here are the basic steps:

1. Drive one or more grounding rods, which are copper or galvanized steel stakes, into undisturbed earth below the frost line. They should be at least 8 feet long for optimal effect.

2. Connect an insulated copper wire firmly from the grounding rods to the metallic frame components. Use irreversible high-compression fittings.

3. Electrically bond sections for prefabricated buildings using splice plates or grounding jumpers to ensure continuity.

4. Terminate the ground wires at multiple leg or corner posts spaced around the perimeter to properly disperse electric currents.

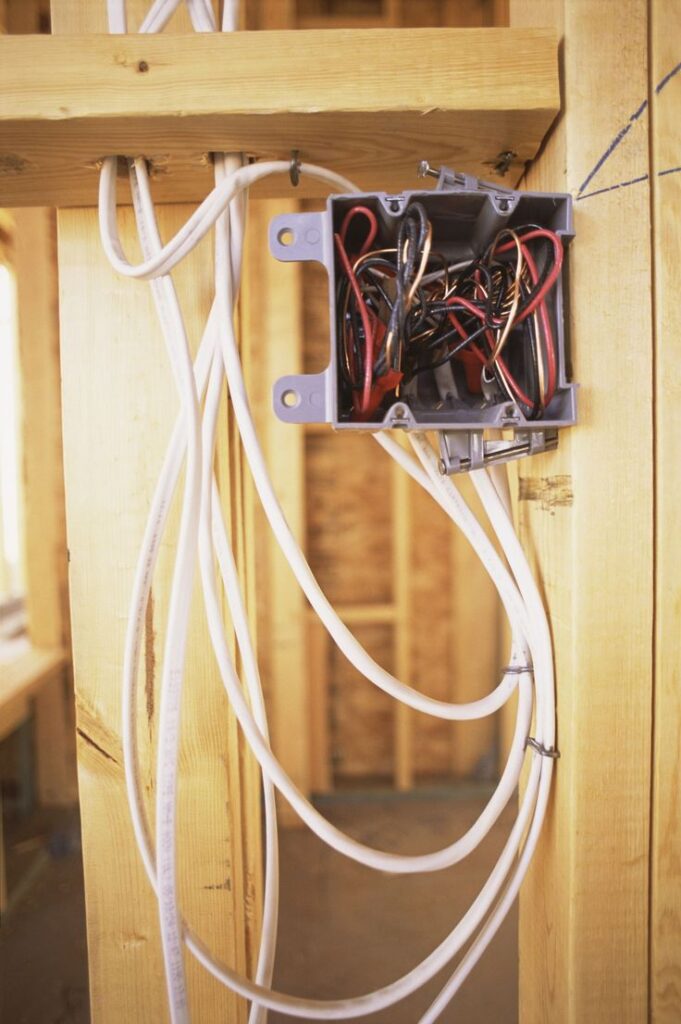

5. Connect any metal vent pipes, service equipment, and electrical boxes to the grounding system per code requirements.

Proper grounding materials, wire gauge sizes, number of ground rods, and bonding methods will vary. Research codes for your area and consult an electrician for project specifics. Annual inspections can also catch potential issues.

Installing ground rods and wires during garage construction is inexpensive when compared to safety and property damage risks. Combined with the need to meet codes, this makes a compelling case for grounding all metal outbuildings. For custom steel buildings and kit garages especially, take the necessary steps to handle stray electrical currents and protect your investment with adequate grounding.