Should Steel Building Kits Be Grounded? An Engineering Analysis

With Garages and Shops utilizing so much conductive metal framing and sheathing nowadays, owners reasonably ponder if electrical grounding protocols also extend to securing overall building integrity, literally “grounding” Steel Shop frameworks defending against lightning strikes or similar energetic atmospheric events. Safety always warrants prudence. However, examining properties behind robust construction and fundamental principles governing electrical earthing schemes has illuminated why most of the grounding options for Steel frame buildings prove utterly unnecessary, if not out-right counterproductive.

Electrical Grounding Purpose

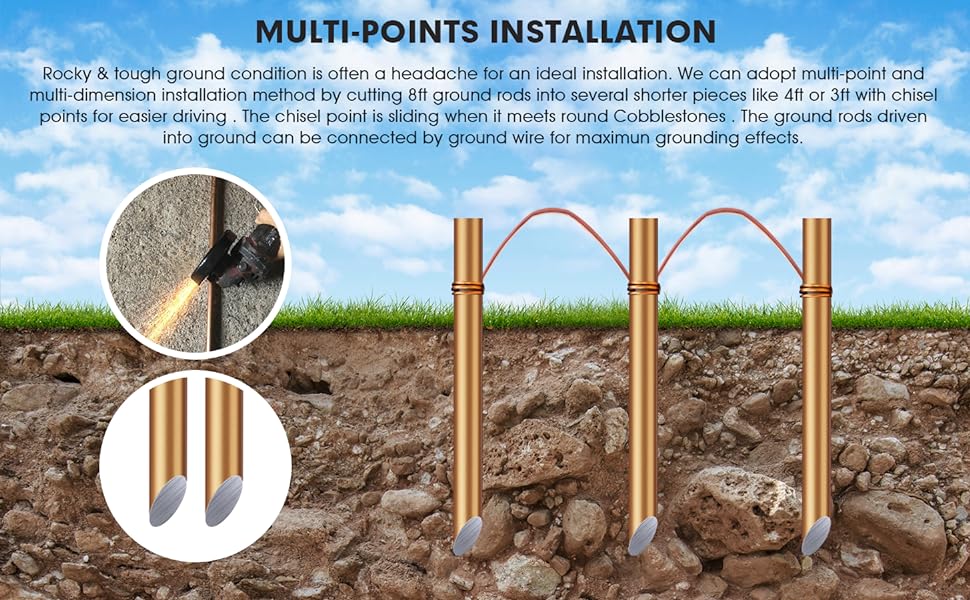

The main function served by bonding conduits, circuits, and appliances to buried grounding rods or concrete-encased electrodes connects to safely handling fault current flows. When live wires accidentally contact frameworks, grounding provides paths of least resistance diverting wayward electricity away quickly before accidental electrocution to you or your electronics can occour. Rapid current detection also triggers overcurrent devices kicking breakers and immediatly de-energizing faulty circuits.

Building Framework Grounding Fallacy

Some assume similarly that creating metallic frame electrical continuity toward earth could guide wayward lightning strikes safely to the ground rather than dangerously through buildings as points of least resistance. However, tall building frameworks already typify apex collection points strikes naturally target with edges concentrating ambient electromagnetic fields that ionize nearby air creating initial conductive plasma channels. Thus lightning already takes paths of least resistance through elevated frameworks as preferential discharge gateways regardless of grounding which only endangers occupants more via flow exposure inside.

Integrity Through Engineering Design

Steel building framework integrity arises from robust structural design withstanding routine environmental forces over decades rather than relying on the earth itself for foundational stability. Rigid steel frame workshops properly constructed focus primal atmospheric energy discharges through main metallic columns and beams instead of randomly arcing across less resilient materials. Fundamental robustness provides security as no ground tethers ever approach the strengths of beams and columns anchoring buildings to foundations built suitably sound for regional demands. This proven engineering leads to generations of properly shielded Garages and shops without unnecessary grounding schemes that could unintentionally do more harm than good.

So in summary, grounding building electrical systems protects those inside from accidental electrocution. But purposefully grounding entire metal building frameworks themselves is functionally superfluous and hypothetically hazardous by attracting wayward high energy discharge effects absent appropriate paths to mitigate damage potential. Trust sound design over gimmicks and money making scams based on false claims of whole house protection.